- Home

- REPORTS & NEWS

- Jetta® Bit

Jetta® Bit

Apr 17, 2019

Bakground

.jpg) When it comes to self-tapping screws, more and more users have virtually abandoned the Phillip or Pozi recess type of fastener because of their tendency to slip, strip or “cam out” while driving them. Instead, they switch to the star recess, because the driver bit fits closely into the recess of the screw head and holds tight when you pull the trigger. The production of screw with a star recess must adhere to the recess specification on the customer’s drawing.

When it comes to self-tapping screws, more and more users have virtually abandoned the Phillip or Pozi recess type of fastener because of their tendency to slip, strip or “cam out” while driving them. Instead, they switch to the star recess, because the driver bit fits closely into the recess of the screw head and holds tight when you pull the trigger. The production of screw with a star recess must adhere to the recess specification on the customer’s drawing.

In order to achieve a full engagement to the recess from all manufacturers, the corresponding size of a traditional star bit is made according to the industrial standard. However, there is always existing wide dimension tolerances among different manufacturers attributed to the tooling and operating factors. As a result, you may find out screws with same size but possess with inconsistent recess dimensions on the market, and the obvious consequence is the loose fit between driver bit and screw.

Jetta® Bit is an improved star screw drive which is sought for developing a fastening system that would provide a firm hold and no wobble than standard star screw and screw driver, and make a virtual increase of the usage lifespan as well as output torque without changing the recess configuration itself. The improvement, in the design of the sidewalls between 6 lobes which were changed from straight into gradient, is meticulously prepared based on our in-depth analytics and precision-forging technique.

DESIGN

Self-Centering

After the Jetta® bit engages in the screw head, the screw is immobilized firmly by the circumferential contact between the sidewalls and screw recess. The sloping sidewalls of the Jetta® Bit fit perfectly in its mating screw head. Once Jetta® bit sticks fit in the recess, the elongations of 6 sloping sidewalls converge in the center of the screw centralizing the applied axial force and stabilizing the fastening process without misalignment.

From the testing result, the tapped hole created by means of Jetta ®Bit is a perfect circle whereas the one by standard star bit appears expanded due to the wobbling phenomena when engaging thick steel plate.

Efficient Torque Transfer

With the unique modification on external geometry, Jetta® Bit is distinguished from the standard star drive that virtually enables to bolster the ultimate torsional torque. The result is that the insertion torque imparted by turning the screw can be resolved into 2 portions : the engaging surfaces of 6 lobes ( standard star bit) and an additional circumferential contact.

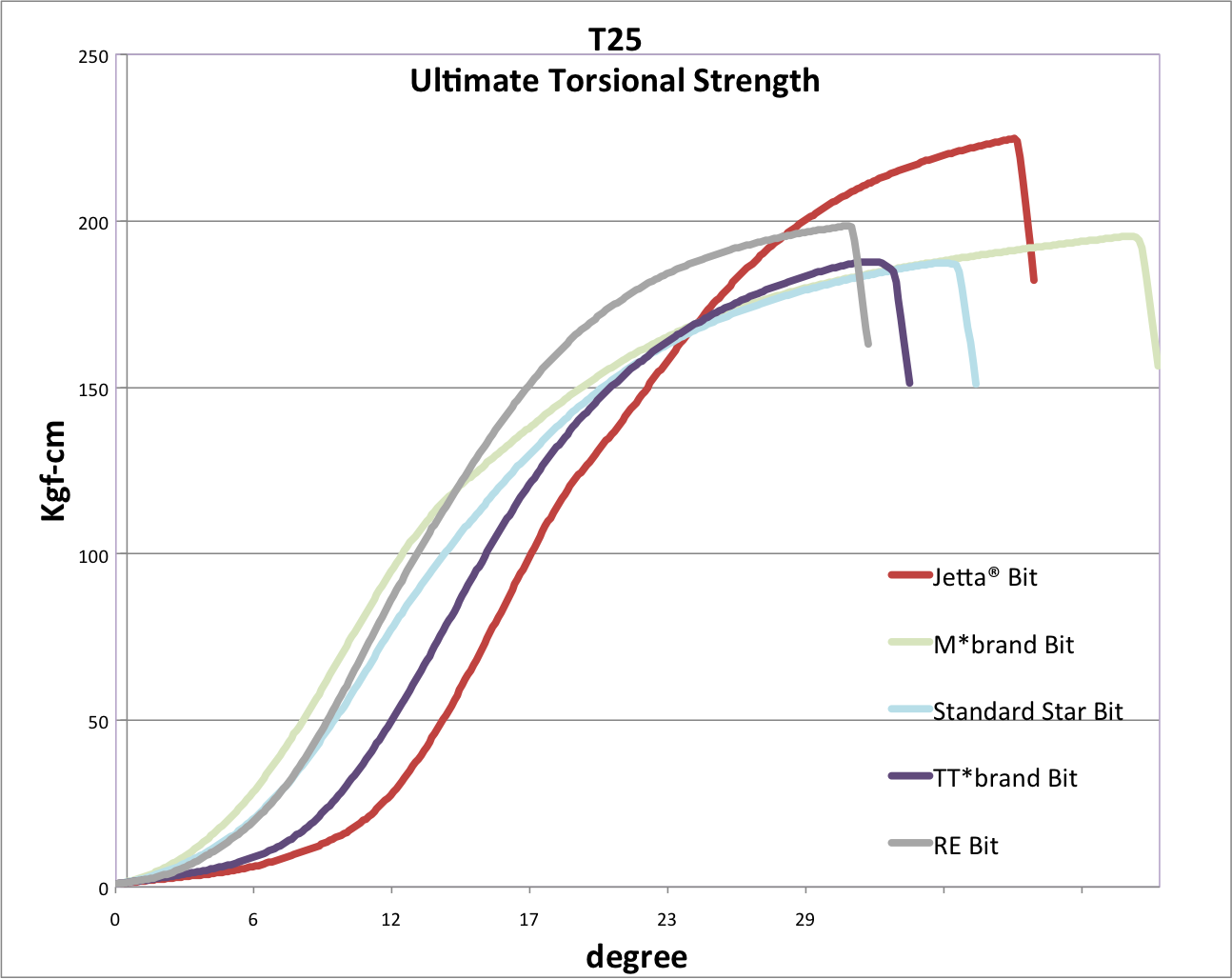

As can be seen in the torsional test, the subtle transformation in geometry endows Jetta® Bit with a distinct reinforcement on the driving performance among other types of star drives. Through the morphology inspections of the breaking surfaces, aside from our patent product, the others suffered apparent plastic deformation under repetitive torque application inducing the crack formation on the hexalobes, whereas Jetta® Bit can still be qualified.

Outcome

-

Before 20 twisting degree, Jetta® Bit bore comparably low stress, hence its lifespan should be the longest.

-

After 20 twisting degree, other bits suffered plastic deformations loosing the turning force;

-

Jetta® Bit started experiencing plastic deformation shortly after reaching 30 twisting degree, but kept adequate turning force until it broke at 38 twisting degree.

-

Under high torque applications, Jetta® Bit could procrastinate the corresponded formation and propagation of crack.