QC POLICY

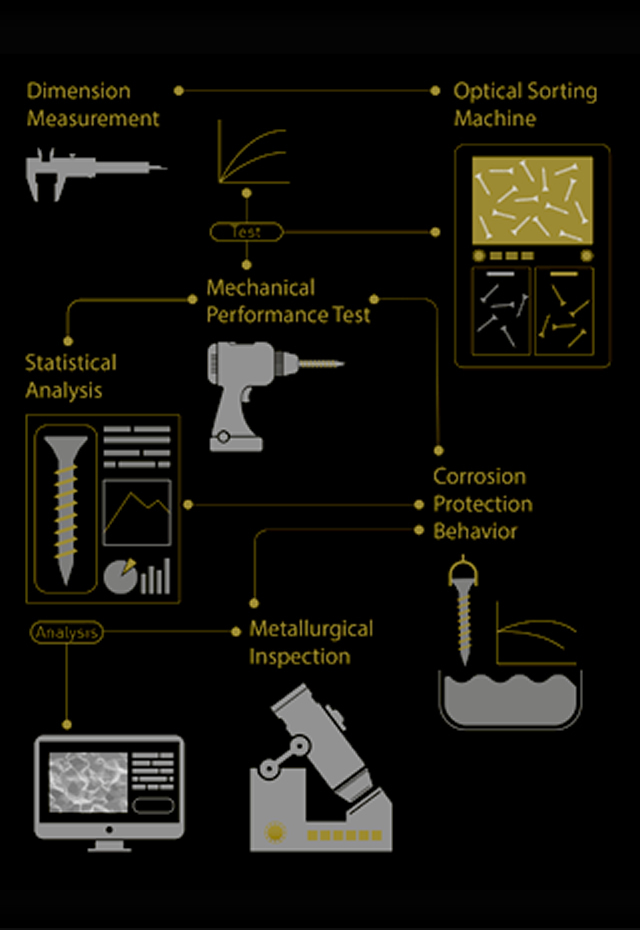

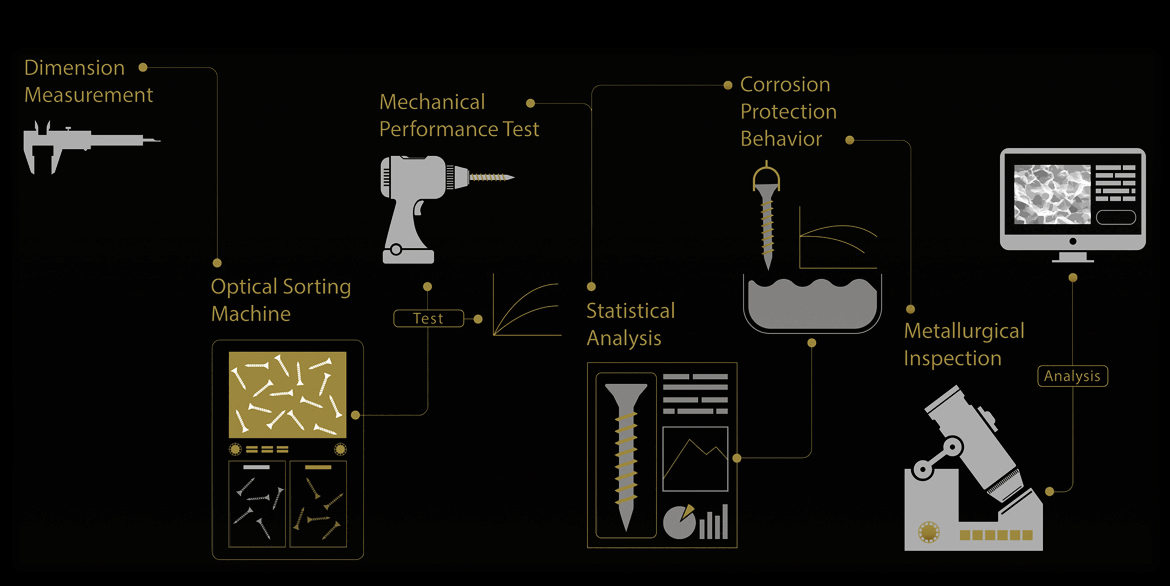

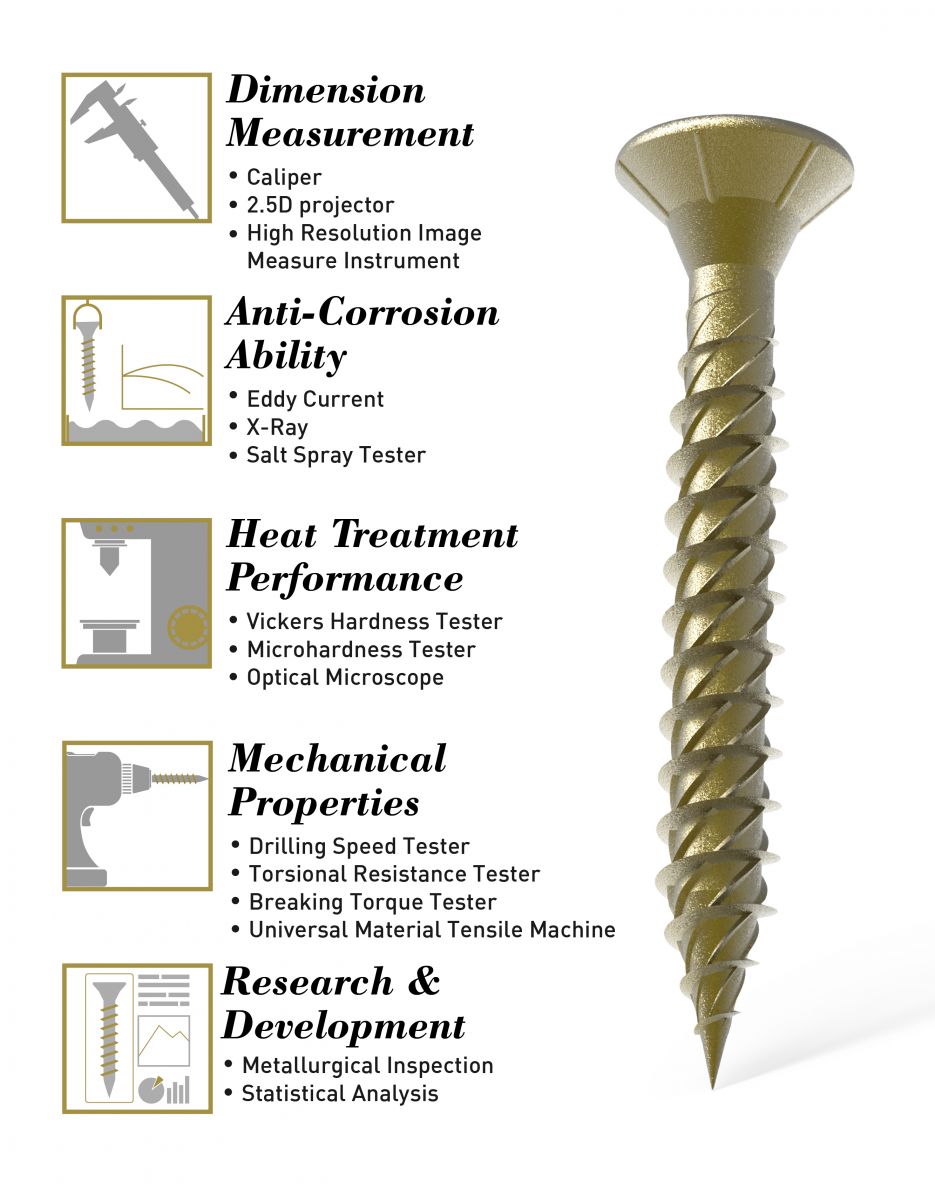

High quality and process reliability are guaranteed by our qualified staff and a laboratory equipped with the latest analytical and measuring systems. The full-time inspections of skilled and experienced staff oversee the company’s carefully control process and industry standards.

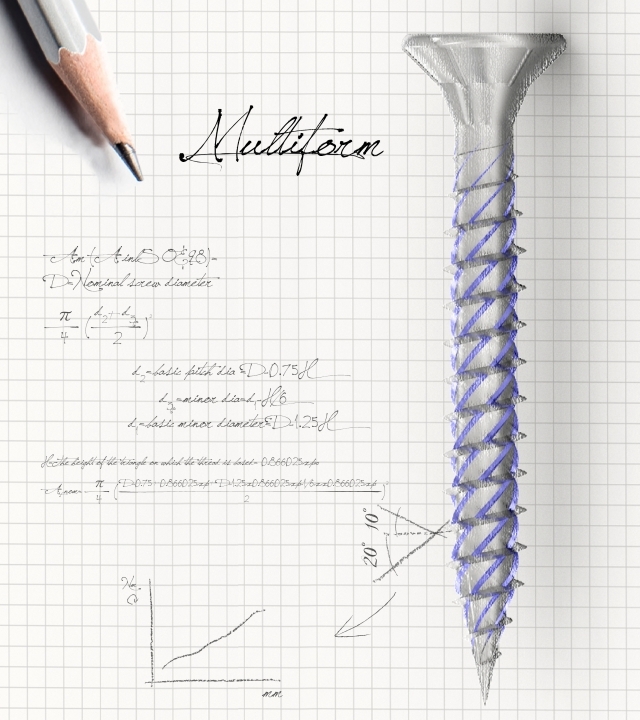

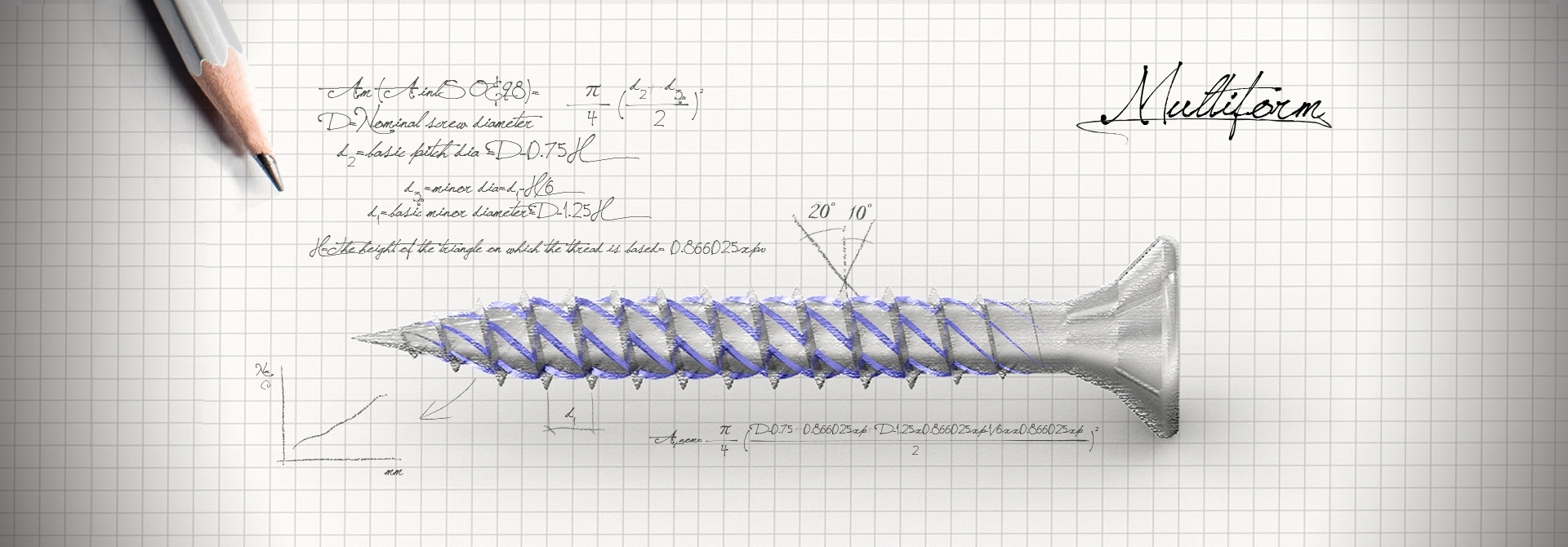

Multiform Fasteners Co., Ltd. possesses full-featured equipments for integrated testings and all of such data declared on the technical reports provides customers having better guidance to the proper usage of the screw. Besides, all important products feature the CE certificates accompanied with official DoP enabling a product to be legally placed on the market in any member state of the European Countries.

.jpg)