- Home

- REPORTS & NEWS

- HyperDriller TDX Screw

HyperDriller TDX Screw

Sep 2, 2020

In the past two decades, the status of wood as a building material has become more suitable for high rise buildings; however only a limited amount of updates have been made to the standards. Wood is an orthotropic material. This means that the stiffness, strength and ductility of wood differ depending on the type and direction of the stressing. In many cases, due to the tension perpendicular to grain dominating the failure, wood is perceived to be a brittle material. However, if designed correctly, wood can fail with a ductile compression failure. In the wood frame construction, the connection design is very important. Only reliable connection can complete the load transmission in the whole structure, and connect each component to form a whole. The load-bearing wall can transfer vertical loads to the foundation, and it can also be designed as a shear wall to resist lateral loads. The roof and floor can withstand the vertical load and also transfer the lateral load to the shear wall. For vertical loads, the floor will transfer the vertical loads (permanent and variable loads) to the studs and then to the concrete foundation; for horizontal loads, the floor will transfer the horizontal loads (wind and seismic effects) to the supporting partitions like the slabs of the shear wall and then transferred to the foundation.

Significant technical advances and developments in the field of timber connections within the last years have fostered the recent renaissance of timber as a structural material. An increased range of connection types and corresponding applications gives designers both opportunity and challenge. The result is a noticeable trend towards systemized solutions enabling quick and reliable assembly on site. Hex head lag screws are fasteners used on tough timbers and hence, often knows as one of the toughest building screws. They can be used for fastening dense timbers with other dense timbers or thin metals. The screws come in a huge size, with a length of one inch and a thickness of quarter inch. In addition to this, they have coarse threads which do not run the entire length of the screw. These screws require a pilot hole to be drilled before being drilled into place. It is advisable to use a nut to secure the fastening in place. Due to the sheer size and strength of these screws, they can handle heavy duty applications with ease. Since the impact of the screws on the surface can be huge, all the components which need to be assembled have to be aligned before using the screws. It is impossible to disassemble a structure once it has been fastened using lag screws. It is available in stainless steel, carbon steel, and alloy steel to bear more wear and tear while also making it more corrosion resistant.

The traditional DIN 571 screws is an early commonly used fastener for attaching lagging, wood braces, shaft hangers or other supports particularly in places where it would be difficult to fasten a bolt, or where the assembled object would suffer heavy load stress, but nowadays people are prone to use the modern structural screw like Jetting® Coach Screw due to the labor-intensive work of DIN 571 screw that requires 2 times pre-drillings of which one for the threads and a larger clearance hole for the shaft. As a result, Multiform Fasteners Co., Ltd. starts thinking to develop a versatile DIN 571 screws that do not require the pre-drilling work but can also outperform the modern structural screw in terms of the load-bearing performance. We collect mass data and parameters from experimental testings to analyze the critical factors affecting the friction resistance, and the adjustments are finally made to compensate for some of the more serious variables of the original DIN 571 Screw. In order to minimize the huge radial stress upon insertion which might split the structural members, the settlement of multiple-thread should be considered to incorporate several cutting mechanisms together.

PRODUCT PERFORMANCE

HyperDriller TDX ( and/ or Jetting® ThunderLag ) Screws is both beneficial to the replacement of DIN 571 screws and can be a better solution for applications bearing high load stress:

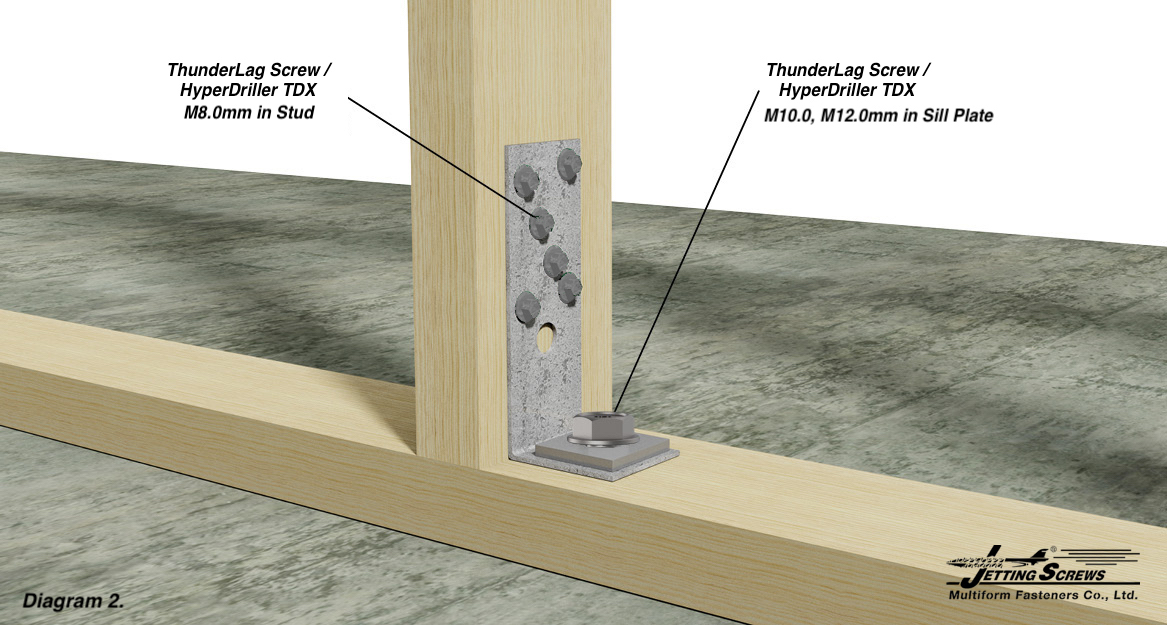

Our RD Department has devoted over year to develop this type of unique items ( HyperDriller TDX & Jetting® ThunderLag ) for load-bearing timber structure. One of the most commonly application is to assemble the CLT prefab wall to foundation/ Wall stud to Sill Plate( Diagram 2.). The good balance of lateral shear stress with minimum driving resistance is realized by the lancing effect of the patented parts trimming off the potential cracks inside the inner hole and ushering in a delightful fastening easiness. Jetting® ThunderLag and HyperDriller TDX, are both complex blend of design, engineering and modern replacements for traditional DIN 571 screws.

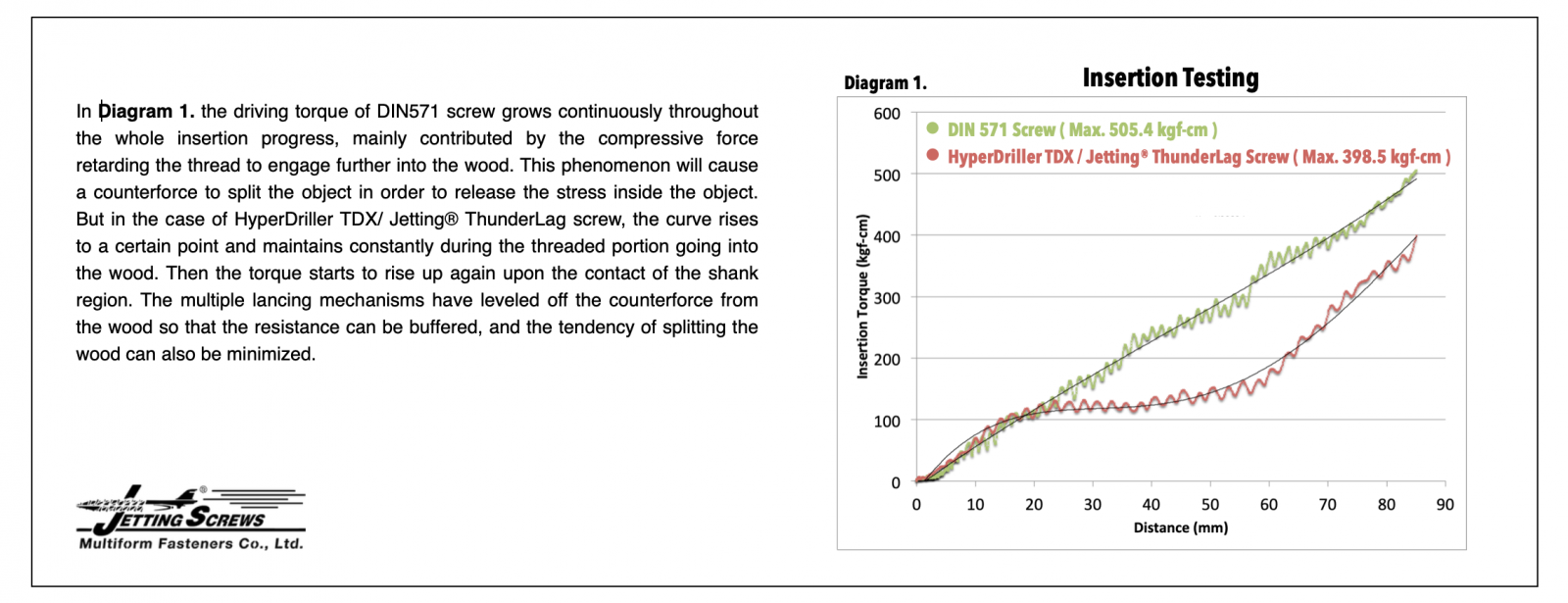

In Diagram 1. demonstrates the insertion testing of HyperDriller TDX/ Jetting® ThunderLag in comparison with DIN 571 screw. The maximum insertion torque of DIN 571 screw is about 100 kgf-cm greater than our products, which indicates that the friction resistance is immense during the whole driving passage.

1. Compared with DIN 571 Screws: Without 2 times Pre-drillings

2. Compared with modern structural wood screws in the same dimension ( Ex. ø = 12mm ):

Torsional Strength > 900 kgf-cm, Bending Angle > 45 degree, No risk of Hydrogen Embrittlement

By simply exerting a rotating torque on the screw with large diameter of the shaft, early DIN 571 screws was limited to penetrate into the wooden beams easily without pre-drillings. The slashing point and big angle saw-teeth are respectively settled to reach for exact, quick starting and facilitate the insertion progress with less ”walking”. The patented cutting grooves (TDX) over the screw body or the intensified rifled shank ( ThunderLag ) can counteract the effect of suppressive stress and mitigate the frictional resistance by its unique mechanism. A built-on round washer head with serrations beneath provides a secure grip force and a professional finish. Please also refer to the Jetting® ThunderLag, with the same unique features but specifically designed with individual fastening mechanisms.