- Home

- REPORTS & NEWS

- Rotation Screw

Rotation Screw

Mar 21, 2019

There are many drawbacks from the conventional chipboard screws/ wood screws such as long insertion time accompanied with high driving resistance, the tendency to split the wooden object and the need of pre-drill for hard material. When fastening an object such as wooden articles, a commonly-used chipbord screw/ wood screw is a screw-in portion with type 17 cutting at the distal end. As the object usually is not pre-drilled in advance, the cutting tip has to be screwed into the object by applying axial force during tapping of the cutting edge; meanwhile, wooden debris are generated by means of the threads wedging into object and then channeled out reversely along the threads. While the threads are screwed in during tapping for a certain distance, the corresponding debris is prone to impede the threads to advance further and generate frictional resistance. Also, the type 17 cutting becomes loss of its primary function as the sharp edge of flute becomes filled up with chips.

Therefore, fastening the prior art chipboard screw/ wood screw requires a greater effort, and the screw hole tends to be pressed generating cracks to result in damage of the object . This weakens the strength of the object and reduces the durability thereof. It also damages the appearance of the object as its surface bulges around the screw especially when the screw is completely driven in, the bulge covers the head appearing an unpresentable look. Moreover, after the screw head of the screw is fastened into the screw hole, the screw hole also is squeezed by the screw head to create other cracks.

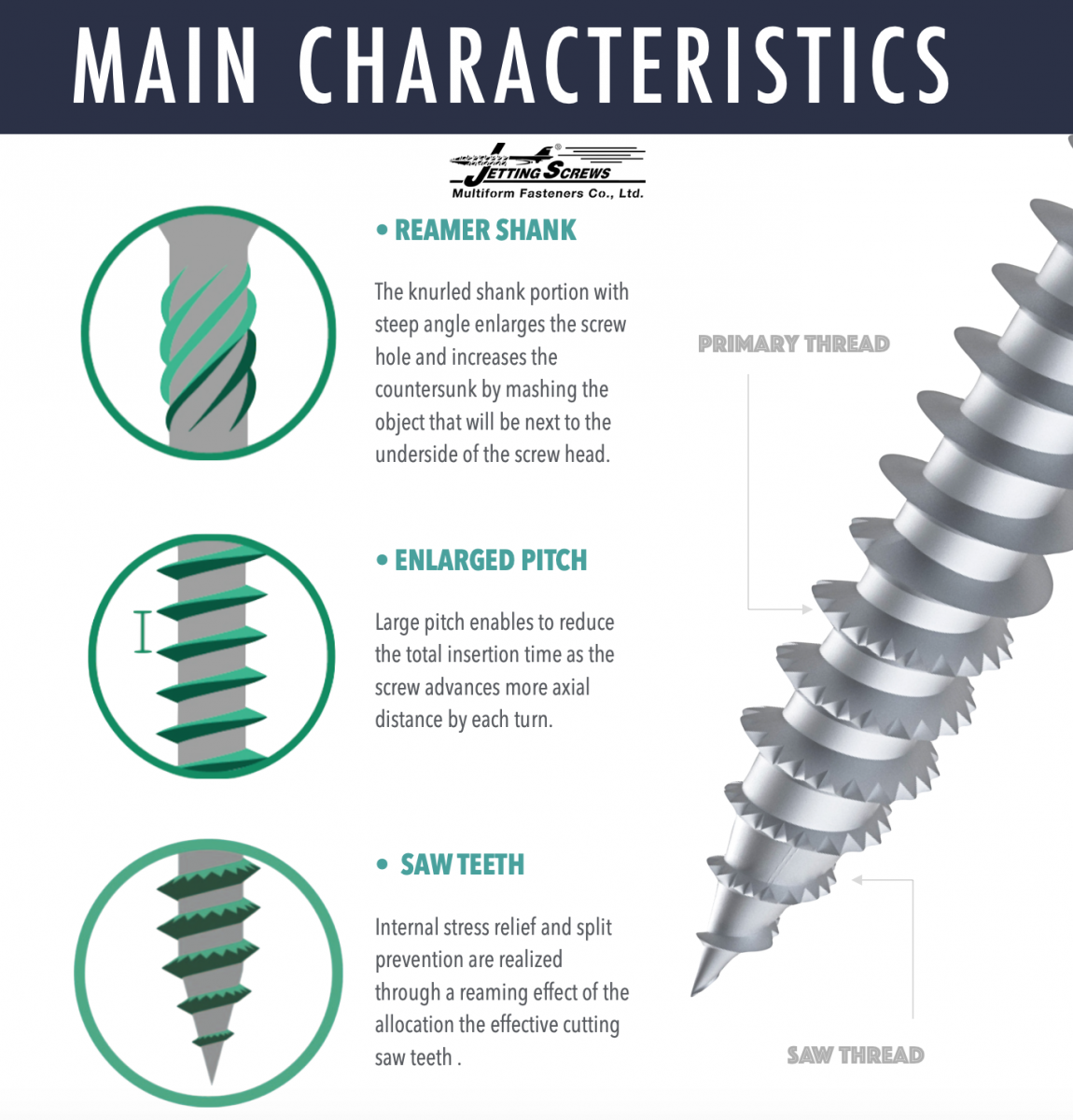

In order to get rid of these unpleasant points that may be encountered by use of traditional fasteners and to provide the practical solutions for customers, Rotation Screw is thus designed and it is the authentically low energy wood screw for penetrating and securing a workpiece quickly and using less energy than conventional chipboard screws/ wood screws. The combination of the various features of Rotation Screw have been designed through empirical trials to significantly reduce insertion time and the amount of torque or energy required to be driven into the object as compared to a conventional chipboard screws/ wood screw while preserving the maximum holding power.

The main features of Rotation Screw is created by milling several convolutions of threads in vicinity of the tapered portion to have cutting recessed surfaces. Each of the cutting surface located in the vicinity of the tapered portion has a saw tooth-like shape combined with Type 17 cutting that could cut the material into relatively small bits on the contact, and drives some of the wood debris out of the wood. Thus, when the screw is being screwed into the workpiece near the ends of boards without predrilling, the recessed surfaces would cut a hole in the wood and release the excessive internal stress, preventing crack formation caused by a forced screw-in as what conventional chipboard screw/ wood screw does. Our recommendation is when driving screws in hard materials, such as PT lumber or hardwoods, opt for a screw in the largest gauge available. For example, many users carry 3" wood screws in #8 gauge, but you'll experience fewer snapped screws if you spend a few extra bucks for #10 screws.

The market has been swamped by numerous brands of screws having similar deployment on the thread profile, however, most of them could merely have the decoration function but not the real benefit for the performance. We consider the comprehensive approaches from the essential property of material to the proper theoretical guideline by means of the disciplined design process for the product development. Multiform Fasteners Co., Ltd. is granted with the Invention Patent for Rotation Screw since 2000, and we have kept progressing with the time to build up a comprehensive Rotation family .